By choosing OMET as a single supplier, companies simplify the production process, reducing coordination time and optimizing the supply chain. This results in a 20% reduction in handling time, leading to quicker market response, lower operational costs and enhanced competitiveness. OMET’s folding and packaging lines are fully customizable to meet specific customer requirements. These lines handle a variety of materials and formats, offering maximum flexibility and quick adaptation to evolving market demands. Thanks to its synergy with PRB Innovation, an Italian company fully owned by the OMET group and specialized in the production of end-of-line packaging machines, OMET provides integrated primary and secondary packaging solutions. These machines are perfectly integrated with production lines, offering highly automated, efficient and complete solutions for the tissue market. Through OMET’s technical consulting services, all lines – from the reel to the finished and packaged product – are connected via modular belt systems, conveyors, diverters, combiners, scales and potential operator passages that ensure a continuous, uninterrupted flow, increasing productivity and minimizing downtime.

HC-200 CARTONER

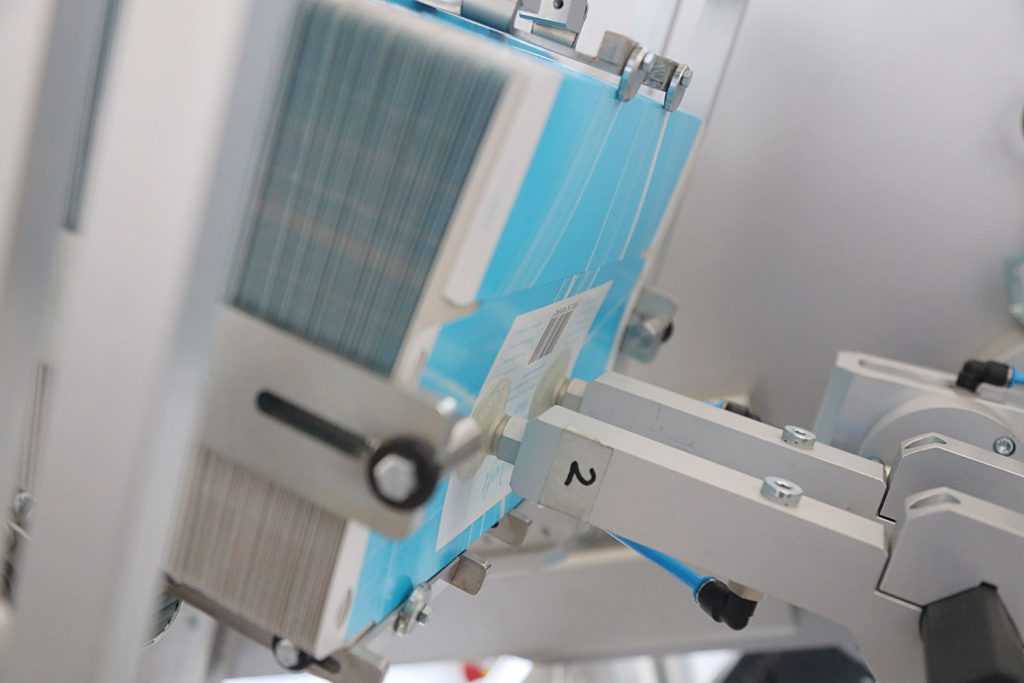

The HC-200 cartoner is an automatic, continuous-motion machine that combines servo technology with an open-frame design. This machine can be fully adapted to meet any requirements, whether for towels or paper napkins, using a wide range of formats from cube to rectangular. It is therefore a flexible machine that allows for quick format changes to meet the specific requests of each customer. With the option of an automatic loading magazine, the machine ensures maximum operational efficiency, as the ease of loading -complete with level control displayed on the screen and equipped with a pre-alarm signal – enables the operator to easily and intuitively manage it. This machine has been developed to handle future-oriented and increasingly sustainable packaging, with reduced maintenance and service costs ensuring savings in product management.

SL-15 AND F30 CASE PACKERS

Compact and fully automated, the SL-15 case packer guarantees maximum reliability and is capable of handling large American-style cartons. Available in a wide range of formats, it is easily adjustable to change product types and box sizes. To further reduce costs and waste, with an even more eco-friendly approach, the SL-15 can be adapted to bypass primary packaging, allowing for direct boxing of loose products from the upstream folding machine. In addition to the SL-15, OMET also offers the F30 model, a vertically-loaded, fully servo-assisted case packer with numerous feeding options, designed to meet specific market needs. Compact, reliable and flexible, the F30 case packer fully accommodates facial tissue products in all possible orientations within the carton, with the ability to work from American cartons to display boxes.

P100 CARTESIAN PALLETIZER

The P100 is a modular Cartesian Palletizer, suitable for both manual and automated configurations. This machine performs automatic palletizing of cartons coming in continuous cycles from the upstream machine onto wooden pallets and can handle everything from half-pallets up to a height of 2,900 mm, with the option of stacking two half-pallets to create a full pallet. This reflects OMET’s true turnkey supply, which also allows for the integration of an automatic wrapping machine with a rotating table or rotating arm.

Flexibility, advanced technology, ease of use

The development and optimization of the machines that make up the line are part of an integrated process where OMET leverages the specific know-how of each sector, from converting to packaging to handling. In lines that integrate different processing stations, the interfaces between units are typically the critical points that reduce the productivity of the entire system. With this in mind, OMET does not only offer the supply of a single package of machines but rather a complete system with a high degree of efficiency.

Omet Srl

OMET is a leading manufacturer of a complete range of tissue converting machines for the high production of neutral and printed napkins in paper, tissue and non-woven materials and paper towels of high quality, in line from roll to finished product. TV 840 Line allows a production speed up to 1.000 mt/min, TV 503 Line, modular folding machine for napkins and table-mats, FV Line for vacuum folded napkins, AS for towels production and ASV for interfolded products.

New Chameleon digital inkjet printing unit, installed in-line on a TV503 machine, allows to print in digital on napkins any image from a pdf direct to print.

Products

Folding lines, Machines for tissue packaging, Napkin machines, Paper converting machines, Paper towel machines.