From the water they use to the waste they produce, manufacturers are striving to reduce their environmental footprint. But, companies tend to forget about the materials that are used on a daily basis – even the smallest products can play a big role in ensuring sustainable operations.

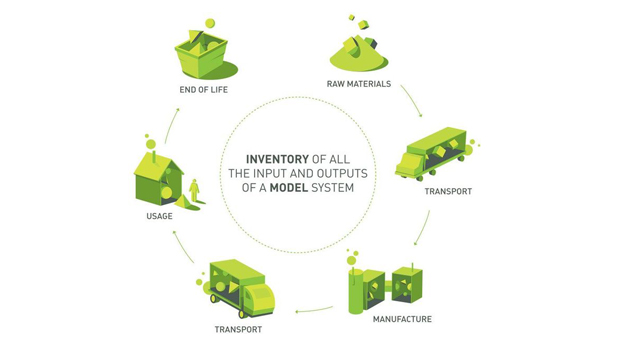

From light maintenance to detailed assembly line cleaning to heavy solvent applications, industrial manufacturers can play an active role in advancing a circular economy model, where resources are continuously recycled and reused, instead of the traditional “take, make and dispose” approach.

The use of recycled products in a business can influence purchases and create new revenue streams by attracting environmentally-conscious customers. For example, stocking wash stations, breakrooms and restrooms with reliable and efficient products helps get the job done without breaking the bank, while also improving brand image and meeting sustainability goals.

Long before sustainable development became fashionable, Cascades were putting the concept into practice by making paper with recycled fiber. Over the course of several decades, Cascades has remained true to this philosophy: use old materials to make new ones, and avoid wasting resources. For example, by using 3.1 million short tons of recycled fiber in 2015, Cascades helped save more than 45 million trees.

Whether a large-scale manufacturing facility or a small automotive shop, products made from recycled materials provide the opportunity to start thinking inside the circle.