These statements on sustainability were part of the philosophy of Peter Wållberg, when he established BIM Kemi in 1973 in rather modest premises in Sweden. It was quickly realised that appropriate innovation was paramount to success. Since then, BIM has become a medium-sized, family-owned company with first class laboratory facilities and personnel, offering great service to customers. From its start, BIM Kemi has been passionate about finding new solutions and innovations for the pulp and paper industry. For us, this means not only working closely with our customers but also to work with others in the industry, leading universities and researchers. Working together opens knowledge exchange, creativity and innovation where fresh perspectives can meet and push the development forward. This is necessary since we need new ideas and solutions to achieve a more sustainable society.

Green chemistry for improved sustainability performance

The tissue industry and paper industry as a whole, has made great improvements in their sustainability performance over the past decades. You could argue that the tissue industry is one of the most sustainable industries today since tissue and paper are so highly based on an easily renewable natural resource and raw material: wood fibres.

However, despite the positive advancements the industry has made, there are still many opportunities for continuous improvement. Consumers, brands and governments are increasingly aware of the threat posed by global warming and habitat destruction.

Your green chemistry partner for pulp and paper

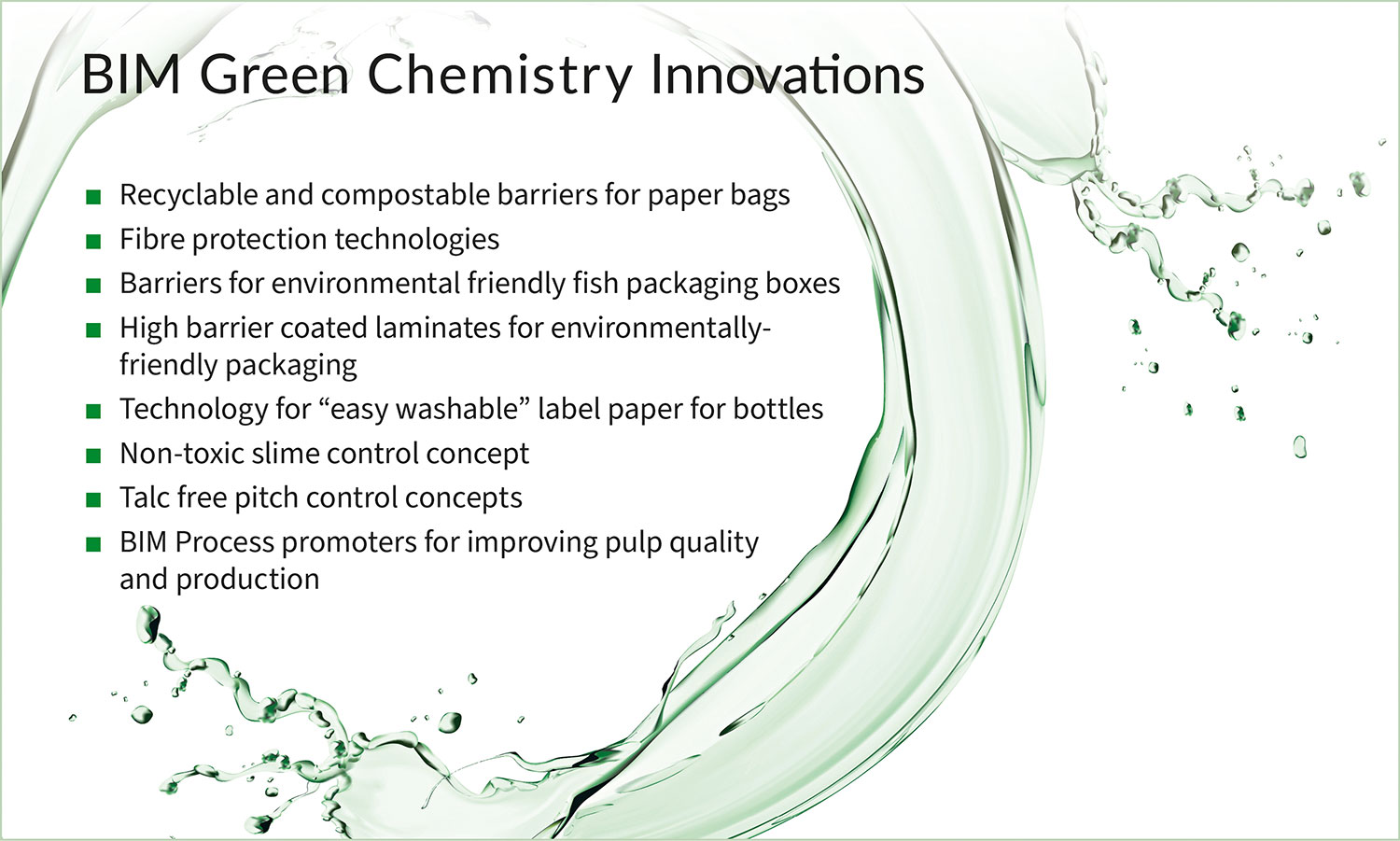

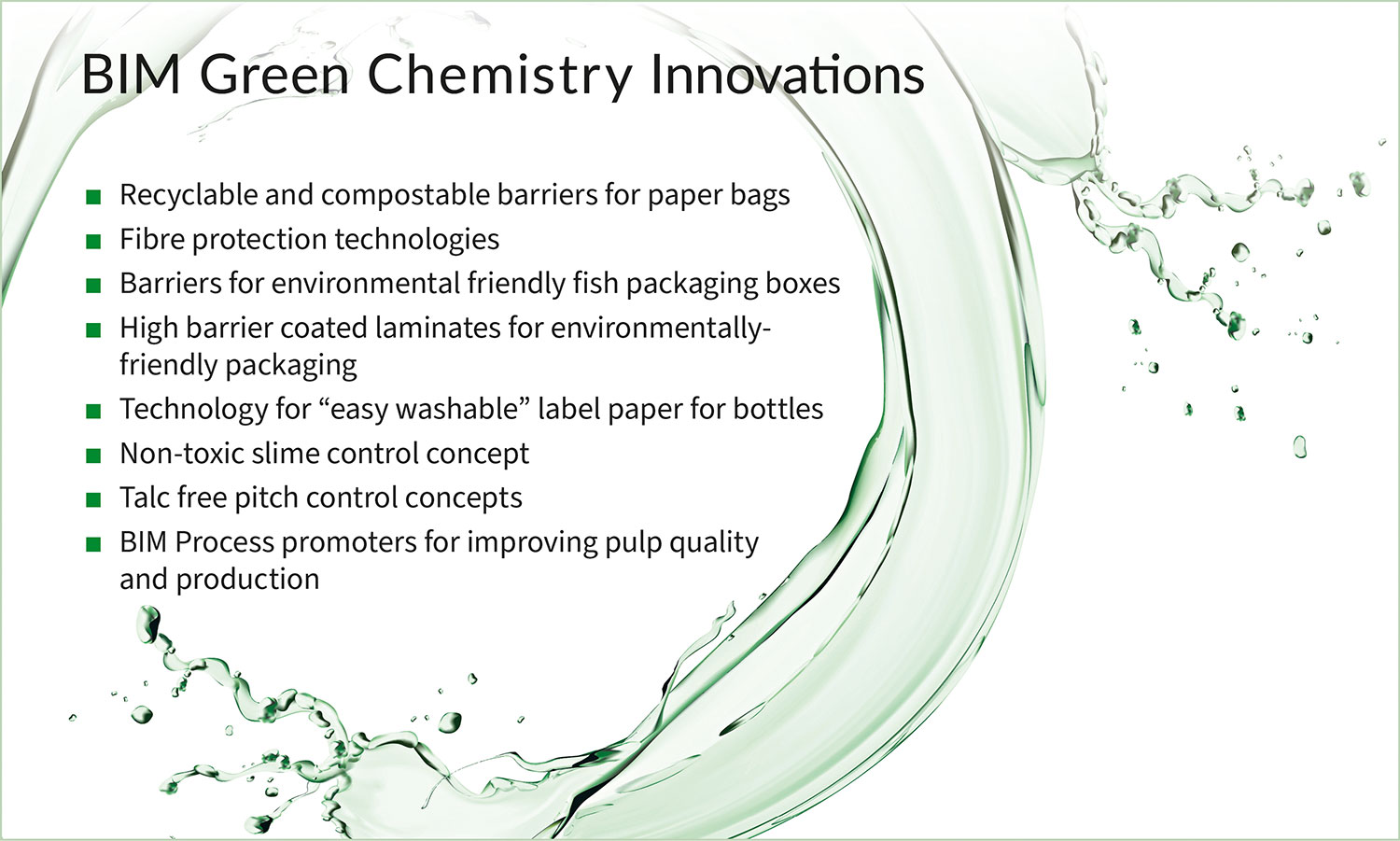

Manufacturers have responded by putting sustainability “at the top of the tree” and implemented many improvements in tissue production. Three key challenges will always remain for tissue producers: Fibre sourcing, Minimising water consumption and Reducing energy use during production. Sustainability measures will grow in importance for tissue producers as they continue to compete on product cost and performance. At BIM Kemi we always provide our expertise to our customers’ sustainability work, ensuring that they get the most out of their manufacturing processes while providing innovative solutions that help producers responsibly manage fibre usage, conserve water, save energy and meet regulatory compliance requirements. Since we are always striving towards a sustainable and green future, we have developed a strategy based on the UN Sustainable Development Agenda and the concept of Green chemistry. Green chemistry at BIM is about applying a holistic mindset throughout the whole life cycle of our products. It means every product needs to meet defined sustainability criteria. This consists of five steps: Resources, Manufacturing, Distribution, Customer Sustainability and End of Product-life. Our objective is to create solutions originating from sustainable sources, that are free from palm oil, biodegradable and renewable.

Innovation has proven to be a pillar in the industry’s strategy to support growth and sustainability. From value-added to affordable products, innovation is necessary to differentiate products in today’s competitive market.

As our head of research, Heino Kuusk says: “there must be room for innovation and a climate to try out new things and ideas in order to be innovative”. This also means that there must be room for failures and the ability and possibility to learn from them, to keep developing. Thanks to our size, we have the possibility to be more flexible.

This makes it possible for us to adapt to our customers’ needs, which can often change. Thanks to our flexibility, there is more room for innovation and we can deliver higher quality to our customers, taking the industry forward.

In essence, it all boils down to two things: to create more value from less resources and making the process efficient, flexible, and profitable for our customers. At BIM we are with you every step of the way.

BIM Kemi

BIM is a family owned specialty chemical company supplying the pulp and paper industry. We focus on creating more value from fewer resources in order to use the world’s limited resources more efficiently.

BIM provide services and concepts all over the world through a global network of experts, production units and R&D facilities. Our headquarter is located in Stenkullen near Gothenburg, Sweden.

BIM in brief

Pulp and paper focus

Founded in 1973

Certified according to ISO 9001 and ISO 14001

Member of the UN Global Compact

Gold rated by Ecovadis

Associated with the Responsible Care Program

These statements on sustainability were part of the philosophy of Peter Wållberg, when he established BIM Kemi in 1973 in rather modest premises in Sweden. It was quickly realised that appropriate innovation was paramount to success. Since then, BIM has become a medium-sized, family-owned company with first class laboratory facilities and personnel, offering great service to customers. From its start, BIM Kemi has been passionate about finding new solutions and innovations for the pulp and paper industry. For us, this means not only working closely with our customers but also to work with others in the industry, leading universities and researchers. Working together opens knowledge exchange, creativity and innovation where fresh perspectives can meet and push the development forward. This is necessary since we need new ideas and solutions to achieve a more sustainable society.

Green chemistry for improved sustainability performance

The tissue industry and paper industry as a whole, has made great improvements in their sustainability performance over the past decades. You could argue that the tissue industry is one of the most sustainable industries today since tissue and paper are so highly based on an easily renewable natural resource and raw material: wood fibres.

However, despite the positive advancements the industry has made, there are still many opportunities for continuous improvement. Consumers, brands and governments are increasingly aware of the threat posed by global warming and habitat destruction.

Your green chemistry partner for pulp and paper

Manufacturers have responded by putting sustainability “at the top of the tree” and implemented many improvements in tissue production. Three key challenges will always remain for tissue producers: Fibre sourcing, Minimising water consumption and Reducing energy use during production. Sustainability measures will grow in importance for tissue producers as they continue to compete on product cost and performance. At BIM Kemi we always provide our expertise to our customers’ sustainability work, ensuring that they get the most out of their manufacturing processes while providing innovative solutions that help producers responsibly manage fibre usage, conserve water, save energy and meet regulatory compliance requirements. Since we are always striving towards a sustainable and green future, we have developed a strategy based on the UN Sustainable Development Agenda and the concept of Green chemistry. Green chemistry at BIM is about applying a holistic mindset throughout the whole life cycle of our products. It means every product needs to meet defined sustainability criteria. This consists of five steps: Resources, Manufacturing, Distribution, Customer Sustainability and End of Product-life. Our objective is to create solutions originating from sustainable sources, that are free from palm oil, biodegradable and renewable.

Innovation has proven to be a pillar in the industry’s strategy to support growth and sustainability. From value-added to affordable products, innovation is necessary to differentiate products in today’s competitive market.

As our head of research, Heino Kuusk says: “there must be room for innovation and a climate to try out new things and ideas in order to be innovative”. This also means that there must be room for failures and the ability and possibility to learn from them, to keep developing. Thanks to our size, we have the possibility to be more flexible.

This makes it possible for us to adapt to our customers’ needs, which can often change. Thanks to our flexibility, there is more room for innovation and we can deliver higher quality to our customers, taking the industry forward.

In essence, it all boils down to two things: to create more value from less resources and making the process efficient, flexible, and profitable for our customers. At BIM we are with you every step of the way.

Products

Adhesives, Anti-foaming agents, Anti-slime agents, Auxiliary chemicals for the paper industry, Bactericides, Biocides, Cleaning agents, Coating additives, Consultancy services, Corewinders, Corrosion inhibitors, Deinking agents, Drainage agents, Dry strength improving agents, Fixatives, Flocculation agents, Fungicides, Glue for converting, Laboratory for analysis and measures, Paper finish improvers, Pitch control, Repulping agents, Sizing agents, Softners, Surface finish improvers, Synthetic mass glueing agents, Tail sealer, Technical service, Wire conditioning agents .