The multiple stages of pulp handling and a great need for water treatment solutions in tissue paper production require a lot of energy. Therefore, improving energy efficiency pays off quickly. Sulzer’s energy audit is a consulting service that aims at improving the energy efficiency of a pumping system. The audit offers actionable insights into what to do to reduce the operational energy consumption and costs. Pulp processing and tissue paper production require a lot of operational energy and contain various phases. An energy audit supports companies in the modernization of their equipment base. It has proven to be especially valuable for paper operators with a large number of aged equipment. All too often, unnecessary energy costs are a result of an over-sized pump or equipment operated outside its optimal point. Changes in processes, planned capacity or in the rest of the process line might lead to a pump operating off its best efficiency point. Tissue paper producers can leverage the results of energy audits in meeting emission-related standards, or when seeking environmental declarations and certificates. The audit can be used to assess and minimize environmental emissions by reducing energy consumption without decreasing the number of equipment or capacity.

We serve essential industries to contribute to a prosperous economy and sustainable society

How the audit proceeds

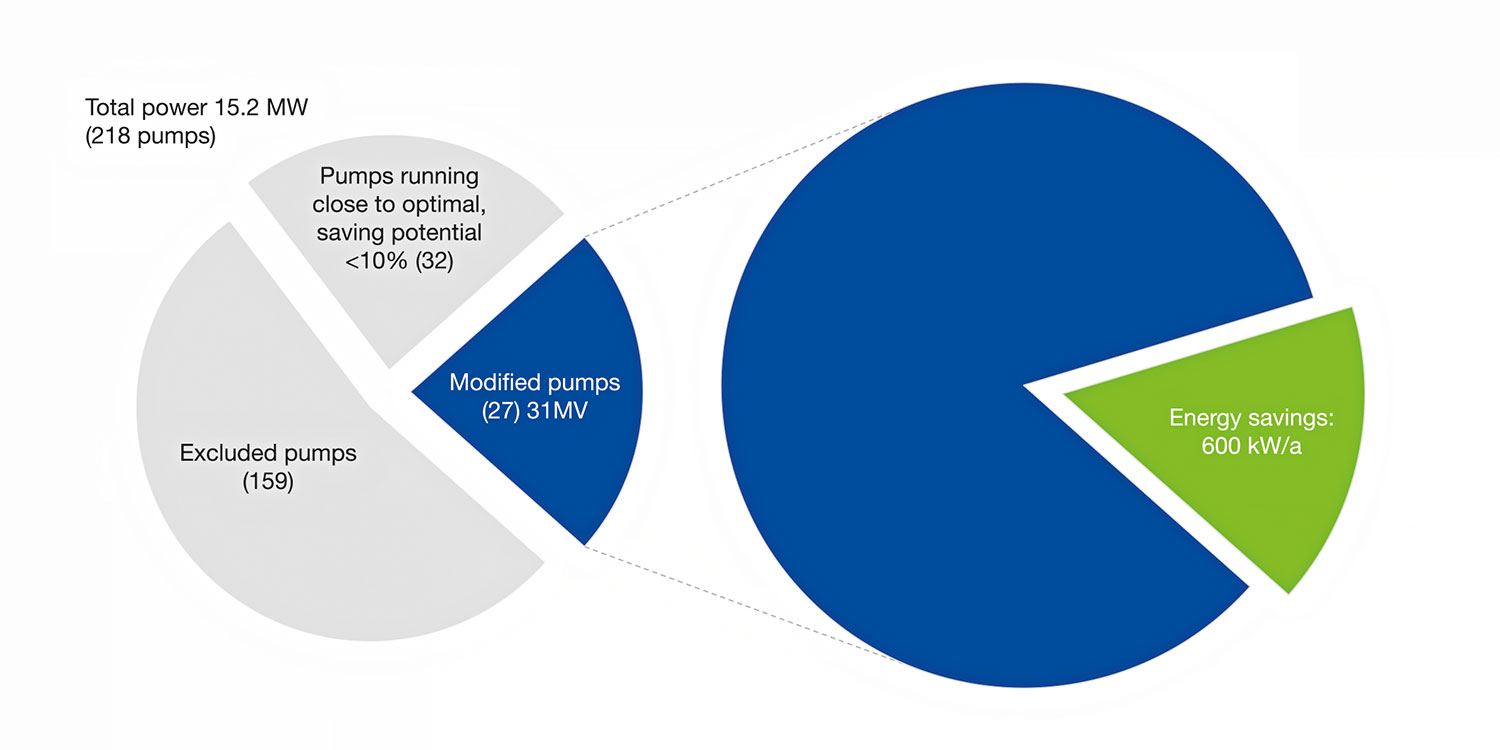

SULZER experts work in cooperation with the customer to review available data sources and define the scope of the audit. The selected scope may contain all equipment at a certain site or process. At large sites, the audits can be done step by step on a predefined selection of equipment. The pumps with the biggest improvement potential are identified and reviewed with the customer. “It is not uncommon that the customer is already satisfied with the audit at this phase, even though the most valuable part is yet to come” – says Pekka Salmi, Head Business Development CSS at Sulzer.

Energy audit report and recommendations

Following the analysis, the customer receives a comprehensive report that contains the current energy usage, identified savings potential, and a detailed list of recommended actions for decreasing energy consumption. To assure usability and easy adoption, the recommendations are completed with cost estimates and payback times for the equipment and site work. The report lists detailed actions to be carried out on the equipment base, enabling reduced energy consumption. The suitable product range, adequate dimensioning, materials of construction and accessories are specified according to the applications.

Two centuries of leadership in the development of innovative products and services

Improved energy savings in pumps, agitators and turbocompressors

As a full-line supplier, Sulzer’s portfolio for the pulp and paper industries offers a range of equipment and efficiency-enhancing accessories to decrease energy usage. Retrofitting is often the most cost-effective method to improve the performance of larger pumps. This involves modifying the impellers to optimize the hydraulic performance or changing the entire hydraulic kit, enabling the pump to operate at the best efficiency point. For smaller pumps, it may be more cost-effective to replace the equipment with more efficient and reliable equivalents. Agitators can also be retrofitted for better energy efficiency. As the selection of Sulzer’s agitators is continuously developed, their performance is improved with each new generation. Most agitators can be upgraded by changing into a newer and more efficient propeller. In addition to pumping and mixing processes, savings can be found also in effluent treatment. Usually, the best way to drive business performance and sustainability goals is to upgrade compressed air applications into modern and more efficient models. Sulzer’s oil-free high-speed turbocompressors provide significant energy savings over conventional compressors. Additionally, with non-wear magnetic bearing units, they offer considerable long-term cost-savings with reduced maintenance.

Sulzer Pumps Finland Oy

Your trusted partner

Sulzer is the world leader in innovative and proven pumping and mixing solutions for the pulp, paper and board industry. These segments offer a very interesting and important scope together with new additional wood raw material based future products. We are committed to this new development.

Intensive R&D with full-scale test facilities and partnership programs set the baseline for our research and development programs. Long-term development forums are imperative for dealing with the fascinating future potential of the industry.

As a full-line supplier, we have a proven track record and excellent references in developing high-efficiency products for a wide range of process applications, including also water and effluent treatment and power plant applications.

Products

Agitator tanks, Air compressors, Centrifugal pumps, Chemical fluid pumps, Chest mixers, High pressure pumps, Mechanical seals, Medium consistence pumps, Mixers, Pulp pumps, Pumps, Seal Supply Systems, Seals, Seals for pumps and valves, Sludge pumps, Spare parts, Standard chemical pumps .