In the industrial production of sectors with high energy consumption, such as the paper industry, energy management is relevant and technology essential.

With a machinery fleet of more than 16,000 units and 1,200 gas turbine-powered industrial cogeneration plants worldwide, 350 of which in the pulp and paper sector (20 with direct drying for the tissue sector), Solar Turbines, a subsidiary of Caterpillar, confirms its leadership in the production of 3.5 to 23 MW gas turbines. But that is not all the team can provide. Today management services make a real difference in plant efficiency.

Solar Turbines partners with its customers operating in various fields on an international scale to analyse possible evolutions of their value chain and create solutions that consider individual needs.

Powering the future through innovative energy solutions

Value Co-Generation and a new service

“We are experiencing a period of extraordinary innovation”, says Paolo Masiero, head of the Solar Turbines Market Development team.

“In recent years, there has been an exponential growth in technological solutions supported by digitisation and IT in all sectors. As a result, we have decided to launch an internal program called Value Co-Generation.”

Borrowing from the term “co-creation,” which implies a close collaboration between supplier and corporate customer, the program focuses on developing further technological solutions and offering consulting services. “What we have done is change the perspective”, explains Masiero. The result is a new and more elaborate concept of service. Underpinning the programme is the rationale of working in partnership with machinery suppliers, in order to identify plant specifications or modifications functional to the results that the customer wishes to achieve. The turbine goes from a standard solution to a fully integrated component of the specific installation.

Evolving toward a Smart Grid

In this context, various departments of Solar Turbines have come into play, each of which follow customers from project definition to plant start-up, with a level of assistance that reaches beyond traditional services and makes use of digitisation.

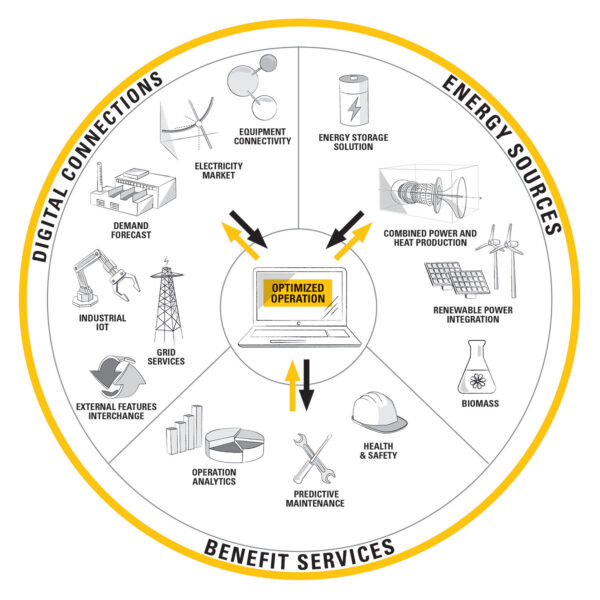

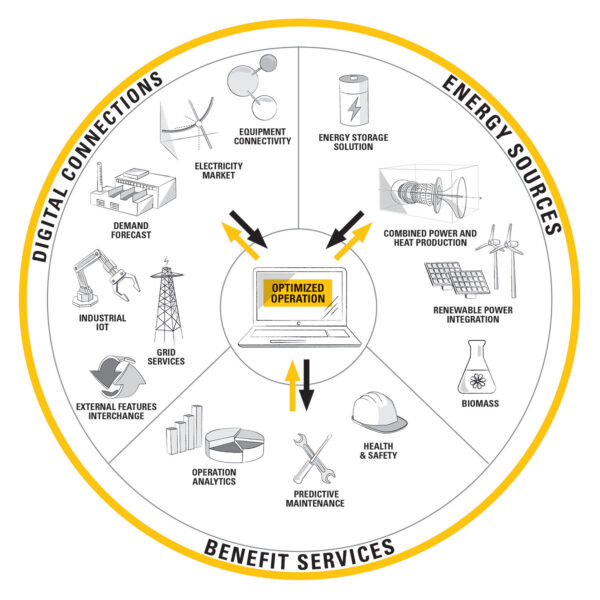

“Through the Insight digital platform, built into the workflow of the Solar Digital business unit that deals with energy optimisation – explains Masiero – we can continually check with the customer and in real time, the production performance of the gas turbine installed. The platform can be linked to the production ERP system and, in some cases, will balance automatically based on the cost of the energy on the grid.” Insight takes account of endogenous and exogenous parameters of the production line, balancing automatically based on the energy demands of the plant, on the one hand, and of the grid, on the other. This IIoT (Industrial Internet of Things) application places the production site within a smart grid. “It is a new concept of service that goes beyond the technologies installed and makes us look at our offering in an innovative way.”

Solar Turbines delivers high value, products and services to customers

Gas: an ideal bridge toward the sustainable economy

The goal is to provide companies with the tools to achieve their sustainability requirements, first and foremost through decarbonisation. This means having sustainable production processes and limiting CO2 emissions. In addition to the patented SoLoNOx combustion system, which minimises the production of NOX, the real step forward has been the development of innovative combustion systems which allows us to be ready today for the fuels of tomorrow. Masiero explains: “Our latest-generation Titan 130, Taurus 60 and T70 turbines, ideal for application in the tissue applications, can burn green fuels: biogas and syngas, both up to 100%, and hydrogen blends of up to 70% and more”. Of fundamental importance is the improvement in the efficiency of the cogeneration gas turbines, which today exceeds 85%, making it possible to obtain substantial reductions in the CO2/MWel produced.

“Gas can thus ferry us towards a totally sustainable economy, with gas turbines proving an excellent means of guiding us towards a highly sustainable future”, adds Masiero. Creating value and sustainability through the careful management of self-generated energy is, therefore, possible. Solar Turbines makes this concretely possible in the tissue sector by combining innovative IIoT technologies with a service system that looks beyond mere maintenance.

Solar Turbines Switzerland SAGL

Solar® Turbines installed more than 1.6 GWe in the Pulp & Paper industry worldwide which correspond to more than 150 installations.

In particular we have been providing gas turbines packages for integrated cogeneration plants in the tissue industry on six continents.

Our packages superior reliability and our granular Customer Services organization enables us to be your supplier of choice everywhere in the world.

Solar® Turbines is a leading manufacturer of mid-range industrial gas turbines (3.5 to 21.7 MW). More than 15,000 Solar units are operating in 100 countries around the world. We are part of Caterpillar Inc., the world’s leading manufacturer of construction and mining equipment, diesel and natural gas reciprocating engines and industrial gas turbines.

In the industrial production of sectors with high energy consumption, such as the paper industry, energy management is relevant and technology essential.

With a machinery fleet of more than 16,000 units and 1,200 gas turbine-powered industrial cogeneration plants worldwide, 350 of which in the pulp and paper sector (20 with direct drying for the tissue sector), Solar Turbines, a subsidiary of Caterpillar, confirms its leadership in the production of 3.5 to 23 MW gas turbines. But that is not all the team can provide. Today management services make a real difference in plant efficiency.

Solar Turbines partners with its customers operating in various fields on an international scale to analyse possible evolutions of their value chain and create solutions that consider individual needs.

Powering the future through innovative energy solutions

Value Co-Generation and a new service

“We are experiencing a period of extraordinary innovation”, says Paolo Masiero, head of the Solar Turbines Market Development team.

“In recent years, there has been an exponential growth in technological solutions supported by digitisation and IT in all sectors. As a result, we have decided to launch an internal program called Value Co-Generation.”

Borrowing from the term “co-creation,” which implies a close collaboration between supplier and corporate customer, the program focuses on developing further technological solutions and offering consulting services. “What we have done is change the perspective”, explains Masiero. The result is a new and more elaborate concept of service. Underpinning the programme is the rationale of working in partnership with machinery suppliers, in order to identify plant specifications or modifications functional to the results that the customer wishes to achieve. The turbine goes from a standard solution to a fully integrated component of the specific installation.

Evolving toward a Smart Grid

In this context, various departments of Solar Turbines have come into play, each of which follow customers from project definition to plant start-up, with a level of assistance that reaches beyond traditional services and makes use of digitisation.

“Through the Insight digital platform, built into the workflow of the Solar Digital business unit that deals with energy optimisation – explains Masiero – we can continually check with the customer and in real time, the production performance of the gas turbine installed. The platform can be linked to the production ERP system and, in some cases, will balance automatically based on the cost of the energy on the grid.” Insight takes account of endogenous and exogenous parameters of the production line, balancing automatically based on the energy demands of the plant, on the one hand, and of the grid, on the other. This IIoT (Industrial Internet of Things) application places the production site within a smart grid. “It is a new concept of service that goes beyond the technologies installed and makes us look at our offering in an innovative way.”

Solar Turbines delivers high value, products and services to customers

Gas: an ideal bridge toward the sustainable economy

The goal is to provide companies with the tools to achieve their sustainability requirements, first and foremost through decarbonisation. This means having sustainable production processes and limiting CO2 emissions. In addition to the patented SoLoNOx combustion system, which minimises the production of NOX, the real step forward has been the development of innovative combustion systems which allows us to be ready today for the fuels of tomorrow. Masiero explains: “Our latest-generation Titan 130, Taurus 60 and T70 turbines, ideal for application in the tissue applications, can burn green fuels: biogas and syngas, both up to 100%, and hydrogen blends of up to 70% and more”. Of fundamental importance is the improvement in the efficiency of the cogeneration gas turbines, which today exceeds 85%, making it possible to obtain substantial reductions in the CO2/MWel produced.

“Gas can thus ferry us towards a totally sustainable economy, with gas turbines proving an excellent means of guiding us towards a highly sustainable future”, adds Masiero. Creating value and sustainability through the careful management of self-generated energy is, therefore, possible. Solar Turbines makes this concretely possible in the tissue sector by combining innovative IIoT technologies with a service system that looks beyond mere maintenance.

Products

Cogeneration, Cogeneration systems + paper drying applications, Energy Saving, Software, Turbine Cabins.